Trailer Tongue and Hydraulic Cover

- Nov 26, 2018

- 3 min read

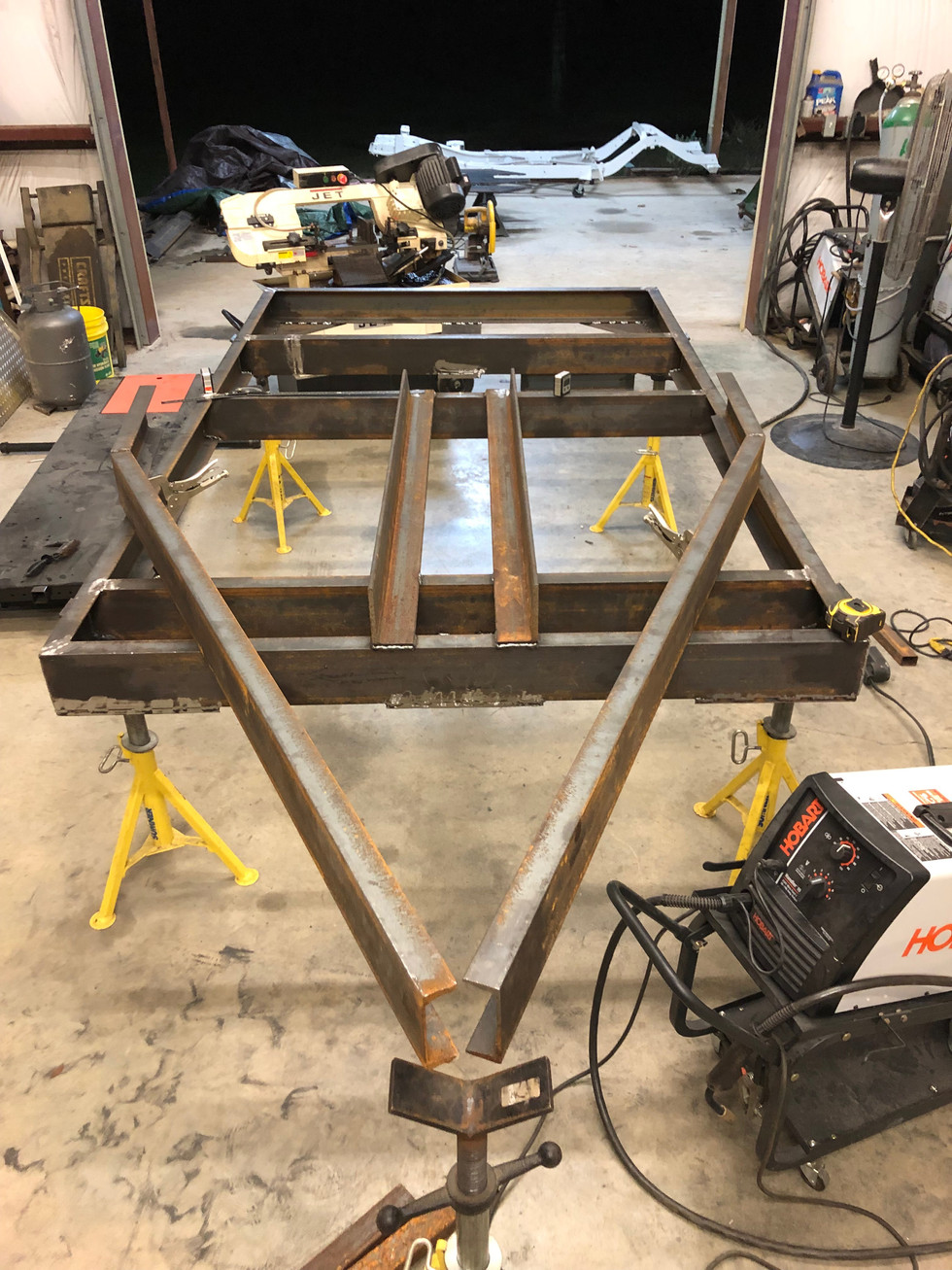

This week we added to the structural integrity of the frame of our trailer. We also were able to attach the tongue of the trailer that attaches to the vehicle pulling the trailer. We attached a protective cover for the hydraulic piston that acts as a debris cover and attachment point. We first welded on steel plates to the top of the trailer that provides structural stability to the frame and a surface for the dump bed frame to rest. Next we took the frame of the trailer and flipped it upside down on top of elevated stands. Once we got it up, we welded the underside of all the cross bracing and supports. This included the bracing for the hydraulic piston that holds it in place and protects the piston from debris. Finally, when it came to the tongue we had to learn how to cut an angle out of the C channel pieces so that we were able to bend them. We used a protractor and a air powered saw tool to cut angles out of the metal. After we put the metal on top of a fulcrum, made up of scrap material, we bent the metal to the desired angle. We double checked our measurements and welded the crease on the metal together. The tongue pieces were then clamped onto the trailer frame and lined up to the desired position.

With the frame completely finished the next step is to weld on the tongue of the trailer and attach the hitch that we previously purchased. After ensuring the welds are capable of withstanding an immense amount of weight we will flip the trailer back over to its normal position. Once we have it up we need to purchase axles, tires, and a jack stand so we can attach them to the frame making the trailer able to hold itself in position. We plan to buy the materials in the next week so we can accomplish our goal of completing the entire bottom half of the trailer. After that we need to build the dump bed frame, attach the hydraulic piston to the trailer and bed frame, and complete the project with electric components and a paint job. Once we finish the main frame of the trailer the remaining steps should go by quickly so that we can complete our project in a timely manner.

What we did well this week was learning from our mistakes. We messed up on building the tongue of the trailer and had to re-cut it until we got it right. We learned that we need to double check everything we do in order to save our time and money. Mistakes can be very costly and we need to take our time to do things right. We took our time after rushing too fast into the situation and completed the tongue flawlessly. We learned we need to slow down and be conscientious of what we are doing so that we do not have to waste our limited time working on the project to fix our own mistakes.

What we need to work on is exactly what we learned. We need to make sure we do not make mistakes so we finish as much of the project as possible instead of redoing certain steps multiple times. We have a lot to learn and need to fully understand things before we run into anything. We are learning as it goes and each week we learn something new that will help us through the entirety of this project as well as our own lives.

Comments